Some Known Details About Sheroz Earthworks

The Main Principles Of Sheroz Earthworks

Table of ContentsGetting The Sheroz Earthworks To WorkThe Sheroz Earthworks IdeasSome Known Details About Sheroz Earthworks Sheroz Earthworks for DummiesAbout Sheroz Earthworks

For any kind of earthwork contractor, it is crucial to execute job with top quality, precision, and on schedule. Utilizing machine control in work equipments allows maximizing the various phases in the earthwork procedure, from planning to the upkeep stage - fj dynamics autosteer review. The machine control system assists the maker operator in attaining the target plane quickly and quickly

The machine control system overviews the driver with centimeter accuracy. With Xsite PRO 3D, you'll always understand precisely just how much to reduce or fill. Your local Xsite technical assistance can assist you and aid with any kind of troubles without going to the site. Remote support saves time and money, as it decreases downtime in jobsites.

The smart Trick of Sheroz Earthworks That Nobody is Talking About

Additional training and guidelines are constantly offered over remote support when required. The earthmoving industry has actually used our field-proven options since the early 1990s. Our system's elements are carefully made to endure the harsh conditions of building sites. Contrast of the very same job executed making use of device control versus the conventional approach reveals that, typically, the standard approach calls for 50% even more time to accomplish the very same task as the technology-assisted approach. https://dzone.com/users/5206373/sherozau.html.

Enter the Xsite device control system; it's right here to supply you with a substantial benefit when functioning with earthmoving machinery. Discover exactly how Xsite Device Control can enhance your productivity and ensure work security! Xsite Equipment Control systems can be set up to any kind of excavator from mini excavators to huge mining excavators.

How does device control job? In 2D systems, the machine is equipped with adjusted disposition sensors.

The system is very easy to find out the essentials can be taught in under one hour of training. With Xsite you do not have to worry concerning discovering all the tips and method at the same time. Added training and directions are always readily available over remote support when needed. Call your regional Xsite dealership to discover even more! Just how does the remote assistance work? A wireless internet connection makes it possible to establish a remote connection between the maker control system and the service center.

Sheroz Earthworks - The Facts

What kind of data styles Xsite systems assistance? Xsite Machine Control systems support open standard data layouts, allowing smooth info circulation from one system to another. Sustained file layouts: 2D-Maps: DXF Point files: DXF, XML, GT, CSV, KOF, PXY Geometry lines: VGP, SBG, XML, Anpakke Surface Models: DXF, XML What components are mounted on my machine? Depending on your choice of system (with or without placing, i.e - fj dynamics auto steering kit price., 2D or 3D), your equipment is furnished with disposition sensors, a controller device, and a display/operating panel.

Many equipment and software application remedies exist to assist figure out a machine's present position on the earth and compare it with a desired style surfaceand building and construction operators can do more to utilize the benefits. Equipment control is using different positioning sensors and a screen to give the operator with a recommendation between the setting of the pail or blade and the target grade.

Depending on the setup, machine control systems can supply the operator with a basic visual overview to container or blade placement, or can instantly move the blade to grade by talking with the machine's hydraulics - https://www.reverbnation.com/artist/sherozearthworks. There are machine control systems readily available for nearly any maker: graders, dozers, excavators, dirt and asphalt compactors, scrapes, leaners, crushing makers, and pavers

Not known Facts About Sheroz Earthworks

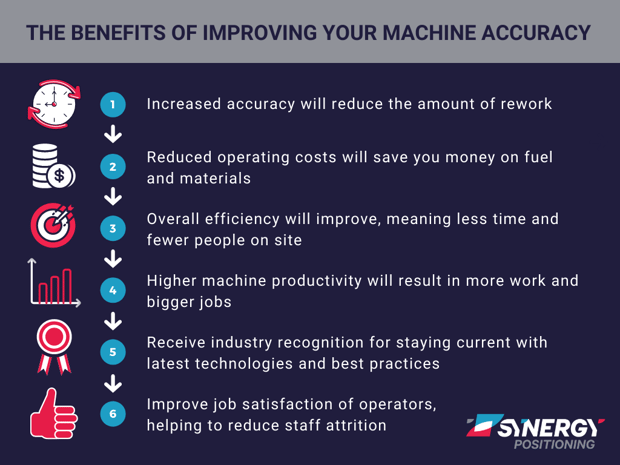

Equipment control can likewise help raise productivity and lower total costs. Building tools without device control will certainly come to be a point of the past and the benefits got from it will certainly be many.

Trimble machine control systems provide a myriad of benefits to anyone that makes use of earthwork equipment and, at EarthCalc, we can offer you with 3D apply for your equipment control-enable equipment. Unsure if machine control is worth the price? Take into consideration the following reasons why you need to consider this choice.

Making use of general practitioner lined up with your 3D design data, these systems basically ensure that you will get rid of or place the appropriate quantity of product at the building and construction website. On most building sites, revamp is a common and aggravating reality, but with Trimble maker control, you can remove the requirement for rework.

Little Known Facts About Sheroz Earthworks.

Frequently, with Trimble equipment control, you can eliminate excess devices at a particular task website. As an example, a job that could have needed using 3 or four pieces of excavating equipment now may need only 2 tools to complete the very same task in less time. This permits you to move your equipment to an additional task site and manage multiple work at one moved here time.